Logo Available for Sale

BREAK-AWAY REEL

The Hogg and Davis, Inc., Break-Away Reel was designed to recover overhead or underground cable, conductor or strand which is to be scrapped.

- No demurrage costs because company reels are no longer being used to ship scrap cable.

- Eliminates the mess and cost of chopping the cable is made into easily handled coils.

- No collapsed reels because the BREAK-AWAY REEL is designed to with stand 50,000 lbs. line pull.

- No scrap penalties because the “Scrappers” do not have to handle messy chopped cable or additional reels.

- Reduce freight costs because nothing is shipped but scrap.

CABLE SHEAVE 424L

The Hogg & Davis, Inc. Model 424 Cable Sheave is proving itself to be the answer to many problems in underground cable pulling. The large 24-inch diameter wheel can be used with standard size cables without the fear of crimping or distortion.

The lightweight aluminum wheel can be used with lead or synthetic sheath cable with no worry of scarring or marking the cable. The 360- degree swivel hook provides a strong anchor and allows the sheave to stay in line with the cable eliminating the problem of the cable “walking out” of the groove.

CABLE SHEAVE 636

The Hogg and Davis, Inc., Model 636 Cable Sheave is a proven solution to many underground cable-pulling problems. The extra large 36-inch sheave can be used with most cables presently on the market – small to large – without fear of distortion or crimping.

The large, smooth groove virtually eliminates scarring or marring of synthetic or lead sheath cables. A 360-degree swivel hook provides a strong anchor and allows the sheave to stay in line with the cable, eliminating the problem of the cable “walking out” of the groove – even when multiple or bundled conductors are being pulled.

EXPANDABLE PAYOUT REEL

This No. 81620 Expandable Payout Reel is designed to work in any position. Made of heat-treated aluminum, these reels can be used singly, or mounted in any combination arrangement on a common stand to pay out multiple coils.

Loading is easily accomplished by folding the spring-loaded fingers located on outside of reel in position. The fingers will only fold in correct direction for use. The unique self-leveling scissors linkage is used to expand or contract the reel circumference to fit wire coils from 16” to 20” in inside diameter, up to 10” wide.

PM10 POLE MUZZLE

Rigged and ready to roll, the PM 10 Pole Muzzle is secured to the pole and facilitates rigging back to the trailer for a solid towing package. The snubbing and cinch chains provide solid capture of the pole. The cinch chain is designed to be used in conjunction with a binding chain back to the trailer. For additional security, the strong-backed PM 10 is slotted for a bolt through the pole’s gain hole.

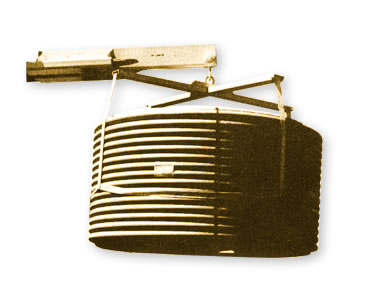

POLY-PIC LIFTING SLING

The 62-4 Poly-Pic System provides the method of handling coiled plastic pipe that eliminates pipe damage. The Poly-Pic System eliminates the use of lift truck forks, pry bars, and hands to separate stacked coils. With a unique design, the Poly-Pic sling grips coils around its circumference. Wide nylon webbing positively grips the coil by forming itself to the wraps of the coil. A positive locking ratchet buckle provides all the power needed for the grip without scratching or marring pipe.

Four (4) vertical legs of the sling insure an even horizontal lift for placement on pallet, truck bed or carousel. The Poly-Pic System can be used with a forklift or crane hook and offers a safer and more efficient method of handling your material.

ROPE REEL

The tremendous crushing forces generated by synthetic rope under strain pose no problem for the Hogg and Davis crush-proof rope reel. Built to withstand the massive pressures that destroy ordinary cable reels, the crush-proof rope reel is constructed for the most rigorous applications and designed to last year after year.

Ordinary reels can’t hold the enormous pressure generated by wound synthetic rope. As the rope is wound onto a reel, it becomes stretched, but, after winding, the rope attempts to retract to its former length. This retraction or pulling creates immense pressures of over 100,000 PSI which can readily crushes ordinary reels, leaving twisted masses of rope tangled around a useless, demolished reel.

RS & SRS 8000

If you already have a flatbed truck or trailer in your fleet and would like to have a multi-reel capacity unit for payout operations — the answer is Hogg and Davis, Inc. SRS8000 reel stand. Also available without swivel base; the RS8000.

The SRS8000 is mounted on a turntable bearing base with locked position every 3 1/2 degrees. This allows the SRS8000 to be positioned at the right pay-out angle without having to move the truck or trailer. When not in use, the SRS8000 can be easily removed from the bed to free the vehicle for other tasks.

SAFETY POLE TONGS

Long recognized as the “standard” in the industry, Hogg & Davis, inc. Safety Pole Tongs have proven themselves time and again in the areas of safety, durability and economy. Timbers or poles are held securely by the triple saw tooth arrangement and cannot slip while under load. Nylatron® pulleys ensure smooth operation of the trip line, which enables the crane, or hoist operator to load and unload poles without putting people in the “danger zone.” Utility companies have increased their pole handling efficiencies by as much as 50% with less labor. Put them to work in your company. Two sizes available to handle most sizes of poles.

UNIVERSAL SHEAVE

These are the advantages of the US-6 and US-20 universal bed mount sheaves from Hogg and Davis, Inc. Both feature tough NYLATRON® sheave wheels to give maintenance free reliability and increase winch life. The center sheave housings rotate 360° for any angle underground or overhead pulls and the slotted center housing is easily removed so hooks, clevises, swivels and other line hardware can pass through without dismantling of line.

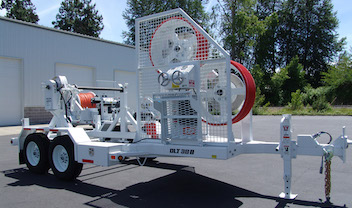

OLT 38B OVERHEAD LINE TENSIONER

The OLT 38B Overhead Line Tensioner is designed to install single conductor. The bullwheels are offset as per IEEE specifications to prevent unnecessary twisting of the conductor during installation. The bullwheels are outfitted with replaceable Diameter Molded segments. Molding of the segments in this manor eliminates the gaps between segments and creates a smooth cable surface. 24″ disc brakes, with centralized braking controls at the operator station allow for precise tensioning of the conductor.

The reel cargo area allows for the carrying of a reel 90″ in diameter and 52″ wide at a maximum weight of 8,000 lbs. A hydraulically actuated 16″ overspin brake is also included as well as a urethane roller fairlead for guiding the cable to the bullwheels.

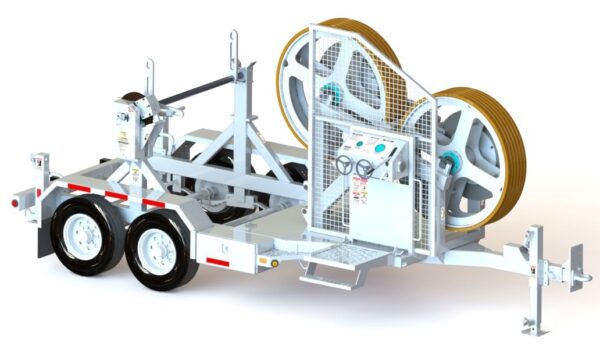

OLT 52B OVERHEAD LINE TENSIONER

The OLT 52B Overhead Line Tensioner is designed to install single conductor. The bullwheels are canted as per IEEE specifications to prevent unnecessary twisting of the conductor during installation. The bullwheels are outfitted with replaceable Diameter Molded segments. Molding of the segments in this manor eliminates the gaps between segments and creates a smoothe cable surface.

36″ stainless steel disc brakes, with centralized braking controls, allow for precise tensioning of the conductor.

The reel cargo area allows for the carrying of a reel 96″ in diameter and 56″ wide at a maximum weight of 12,000 lbs. A manually actuated bronze overspin brake is also included as well as a urethane roller fairlead for guiding the cable to the bullwheels.

OLT 72B OVERHEAD LINE TENSIONER

The OLT 72B Overhead Line Tensioner is designed to install single conductor. The bullwheels are canted as per IEEE specifications to prevent unnecessary twisting of the conductor during installation. The bullwheels are outfitted with replaceable Diameter Molded segments. Molding of the segments in this manor eliminates the gaps between segments and creates a smooth cable surface.

48″ Diameter 1045 carbon steel disc brakes, with centralized braking controls, allow for precise tensioning of the conductor.

Fairleads are adjustable for multiple setups. Front to back, left to right to tower, and right to left to tower.

CRP140 MULTIPURPOSE DOLLY

In the tradition of its multi-purpose trailers, Hogg & Davis, Inc. brings you the CRP140. Available in single or multiple reel configurations, the CRP140 offers complete job support hauling capabilities. Optional pole bolsters add to its versatility to make it the only trailer you’ll need. Its 14,000 lb. tandem axle design provides stable, smooth hauling. Its rugged 11 ga. formed steel sides provide solid protection against the banging and abuse cargo bodies endure. This one’s built for the long haul.

H135PP POWER REEL DOLLY

The H135PP is the “foundation” of the Hydra 985. With its self-contained power pack this unit features hydraulic loading and self-maneuverability in the yard and at the job-site. Its rugged, open yoke, rigid frame gives it the strength required for tough use, even in off-road applications.

The H135PP is a modular approach to line construction equipment. A Power Unit can be added to the H135PP to create full cable pulling capabilities. All power unit mounting rails and cylinder anchors are incorporated into the H135PP. So, as your requirements grow, the H135PP can grow with them. This system reduces equipment obsolescence and future capital expenditures. Above is an example of one conversion possibility – the H135PP can become the Hydra 985. The Hydra 985 is our diesel powered 24,000 lb. line pull cable reel unit.

PT150 POLE TRAILER

The PT150 Series pole trailer is the high capacity version of our PT100 series. It has dual wheels, single axle 16,000 lb. GAWR and a capacity of up to 14,000 lbs. It has three models: (S) features a short drawbar, (L) a long rigid drawbar, and (T) a telescoping drawbar.

Setting the PT150 apart from the competition is its unique hydraulically actuated idler wheel. The double A-Frame mounted assembly provides 360-degree swivel and ease of motion with its bearing mounted 8-inch caster. The hydraulic pump is easily accessible at the curb-side of the unit. Dual coil springs retract the wheel for towing.

R40 REEL DOLLY

5000 lb. Payload, 72″ x 50″ REELS Hydraulic Loading, Single reel capacity, single axle, tubular steel construction.

Hydraulic Loading, Multiple pocket mandrel lifting racks can load reels up to 72″ diameter and 50″ wide. The system is designed to carry reels with uniform ground clearance and to carry reels at the lowest possible center of gravity for better towing.

Racks are stabilized and locked mechanically to transfer load from the hydraulics to the mainframe.

STELLAR HOG

The Stellar Hog Transport System features a patent-pending concept of a variety of modular components being transported by a single trailer system to provide highly versatile daily operations and rapid response in emergency situations.

The most commonly used module is a specialized reel pallet. This pallet will carry reels 96 to 130-inch diameter; up to 84 inches wide, weighing 20,000 pounds.

Other modules currently under design to customer specs are portable generation, portable substations, field offices, switching centers, machinery transports, refuse bins, etc.

T150 CABLE REEL DOLLY

The Hogg and Davis, Inc. Model T150 Cable Reel Dolly is an open yoke unit designed for low center of gravity reel hauling. It offers operating ease and simple maintenance. The 4” x 6”, 1/2” wall tubular frame, super-structure and heavy duty fenders and panels are integrated into a structurally strong and rigid unit designed for years of rugged service. it is backed by the years of experience, knowledge and quality which Hogg and Davis, Inc. represents.

With a 4-cycle, single cylinder, overhead valve, air-cooled, gasoline, pressure lubricated, with oil filter, vertical shaft, aluminum head and block engine. Mounted on a 15-gallon hydraulic reservoir with submerged hydraulic pump. Electric start with rope crank for back up.

Other modules currently under design to customer specs are portable generation, portable substations, field offices, switching centers, machinery transports, refuse bins, etc.

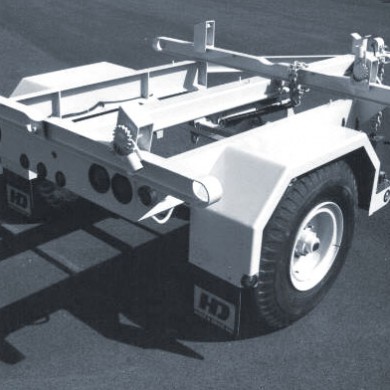

TH40 POLE & REEL DOLLY

The Hogg and Davis, Inc. Model TH40 means versatility. Fast becoming the industry standard workhorse, the TH40 combines the most sought-after features into a smooth operating, long-lasting, compact unit.

The key to this unit’s popularity is hydraulics. The hydraulic mandrel lifts and idler wheel allow one man to load or unload reels without delaying other pieces of valuable equipment. Gone is the necessity of boom trucks standing by. Gone is the need for three or four men to wrestle heavy reels. The TH40 pays for itself in manpower savings alone. The TH40 is built to meet the requirements of any utility engaged in strand and cable transporting and stringing, or pole and material handling; designed for the most demanding.

.

PROPERTY LINE DOLLY

The Hogg & Davis Property Line Dolly introduces new versatility and efficiency to the transporting of materials to hard to reach property line jobs.

Transformers, poles, power units, and wire reels can be handled with a minimum of work, and costly set-ups are eliminated for underground cable jobs requiring winch work in rear property line areas; as well as buildings or apartment house basements.

HP6500 “BOSS HOG” HYDRASTATIC PULLER

Optional Equipment

- Hydraulic Tool Circuit runs light duty tools such as pump, 10 GPM pump

- Hydraulic Rear Capstan – rear mounted on left side provides 90-100 FPM, 1,000 lbs. pull; solenoid controlled with directional switch

- Outriggers – hydraulically operated rear stabilizers

- Feeder Tubes – allow storage of long and short feeders used in underground placement operations

- Hydraulic Hose/Reel – rear fender mounted retractable reel/hose

- Beacon Light – fixed or telescopic pole mounting strobe light

- Urethane Drive Rollers advanced friction material for extra durability

- The optional Levelwind LW3 – semi-automatic, solenoid controlled for level winding onto the drum.

HYDRA 985 “THE HYDRA HOG”

Product Features:

The Hydra 985 develops whatever pull is necessary to overcome the resistance on the line. Pulls up to 24,000 lbs. can be developed to handle the most stubborn pulling situations. Line pull ratings are “bare drum” ratings measured with a dynamometer and achieved on a Model 8050 Break-Away Reel. Ratings will diminish or increase depending on the size reel used, its flange width, core diameter and amount of line on the reel. High coefficient of friction rollers assure best performance possible on any given reel.

HYDRA 135-C CONVERSION

General Specification

Power Steering Conversion:

Add this conversion to provide easy maneuvering to your unit. Includes rotary actuator activated idler wheel, complete controls and new drawbar cylinder with integrated holding valve. Now you can move your unit easily into those “tight” spots on the job.

Bearing Mandrel Rack Conversion:

Add this conversion to improve smoothness of payout and pulling operations while eliminating wear and tear on components. All metal-to-metal contact is eliminated with the use of Nylatron® mandrel bearings. Includes racks, bearings, bearing blocks and new reel mandrel.

See HYDRA 985. for complete specifications.

ODP 100PPS DRUM PULLER

The ODP 100 is a single drum puller capable of line pulls of up to 10,000 lbs. Pulling is controlled with an electric over hydraulic friction joystick allowing for infinite control of line speed and presettable line pull, and the operator controlled post style levelwind allows for even winding of rope. Disengaging the drive system allows for free wheel payout of the pulling rope with an integrated hydraulically controlled overspin brake.

ODP 20-4 DRUM PULLER

The ODP 20-4 is a four drum puller capable of line pull of 2,000 lbs on a single drum. Each drum can be engaged or disengaged for single or multiple drum pulling. An overspin brake with a hydraulic brake caliper is also included on each drum. The automatic diamond lead screw levelwind allows for even winding of rope on one drum at a time. Optional dual levelwind available.

ODP 200 DRUM PULLER

Trailer or truck mounted, this large transmission puller is capable of line pull of 20,000 lbs. Equipped with a John Deere Tier IV diesel engine, dual planetary drives and a rope capacity of 22,000 ft, this machine is ready for the large jobs.

ODP 30 DRUM PULLER

The ODP 30 is a single drum puller capable of line pull or tension of up to 3,000 lbs. Disengaging the drive system allows for free wheel payout of the pulling rope with an integrated hydraulically controlled overspin brake. The operator controlled post style levelwind allows for even winding of rope.

All unit functions are centrally located at the operators station. Engine gauges including tachometer, oil pressure, temp, fuel, and voltage are all in view. Pulling is controlled with an electric over hydraulic friction joystick allowing for infinite control of line speed and pre-settable line pull.

ODP 30-4 DRUM PULLER

The ODP 30-4 is a four drum puller capable of line pull of 3,000 lbs on a single drum. Each drum can be engaged or disengaged for single or multiple drum pulling. An overspin brake with a hydraulic actuator is also included on each drum. Operator controlled post style levelwind allows for even winding of rope.

All unit functions are centrally located at the operators station. Engine gauges including tachometer, oil pressure, temp, fuel, and voltage are all in view. Pulling is controlled with an electric over hydraulic friction joystick allowing for infinite control of line speed and pre-settable line pull.

ODP 40 DRUM PULLER

The ODP 40 is a single drum puller capable of line pull up to 4,000 lbs. Disengaging the drive system allows for free wheel payout of the pulling rope with an integrated hydraulically controlled overspin brake. The operator controlled post style levelwind allows for even winding of rope.

All unit functions are centrally located at the operators station. Engine gauges including tachometer, oil pressure, temp, fuel, and voltage are all in view. Pulling is controlled with an electric over hydraulic friction joystick allowing an infinite control of line speed and preset-able line pull.

ODP 40-4HRC DRUM PULLER

The ODP 40-4 HRC (High Rope Content) is a four drum puller capable of line pull of 4,000 lbs on a single drum. Each drum can be engaged or disengaged for single or multiple drum pulling. An overspin brake with a hydraulic actuator is also included on each drum. Operator controlled post style levelwind allows for even winding of rope.

All unit functions are centrally located at the operators station. Engine gauges including tachometer, oil pressure, temp, fuel, and voltage are all in view. Pulling is controlled with an electric over hydraulic friction joystick allowing for infinite control of line speed and presettable line pull.

ODP 60 DRUM PULLER

ODP 60 DRUM PULLER

The ODP 60 is a single drum puller capable of line pull or tension of up to 6,000 lbs. Disengaging the drive system allows for free wheel payout of the pulling rope with an integrated hydraulically controlled overspin brake. The operator controlled post style levelwind allows for even winding of rope.

All unit functions are centrally located at the operators station. Engine gauges including tachometer, oil pressure, temp, fuel, and voltage are all in view. Pulling is controlled with an electric over hydraulic friction joystick allowing for infinite control of line speed and presettable line pull.

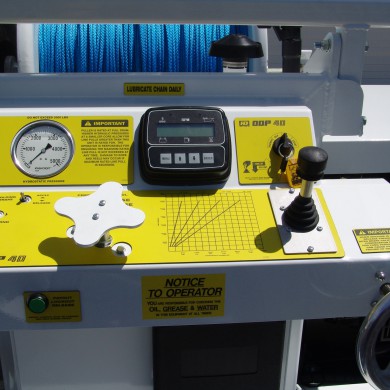

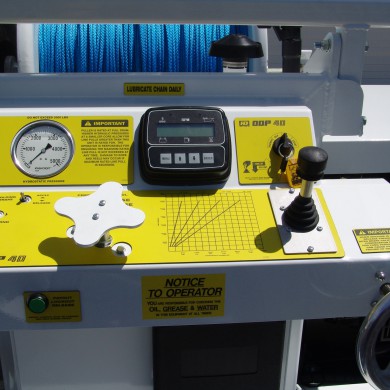

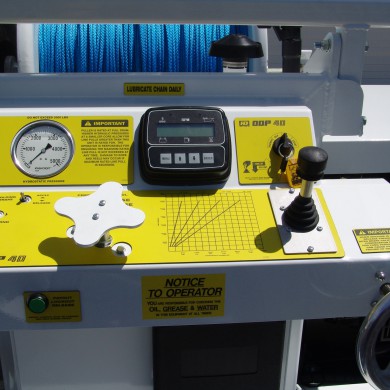

ODP 100PPS DRUM PULLER

The ODP 100 is a single drum puller capable of line pulls of up to 10,000 lbs. Pulling is controlled with an electric over hydraulic friction joystick allowing for infinite control of line speed and presettable line pull, and the operator controlled post style levelwind allows for even winding of rope. Disengaging the drive system allows for free wheel payout of the pulling rope with an integrated hydraulically controlled overspin brake.

All unit functions are centrally located at the operators station. Engine and hydraulics system gauges including tachometer, oil pressure, temp, voltage, hydrastatic pressure, and overspin brake pressure are all in view, and a PowerView Engine Info Center allows the operator to monitor all functions of the power unit.